Information Details

What are the placement methods of hardware parts in precision metal processing?

Release time:

2023-06-06 15:58

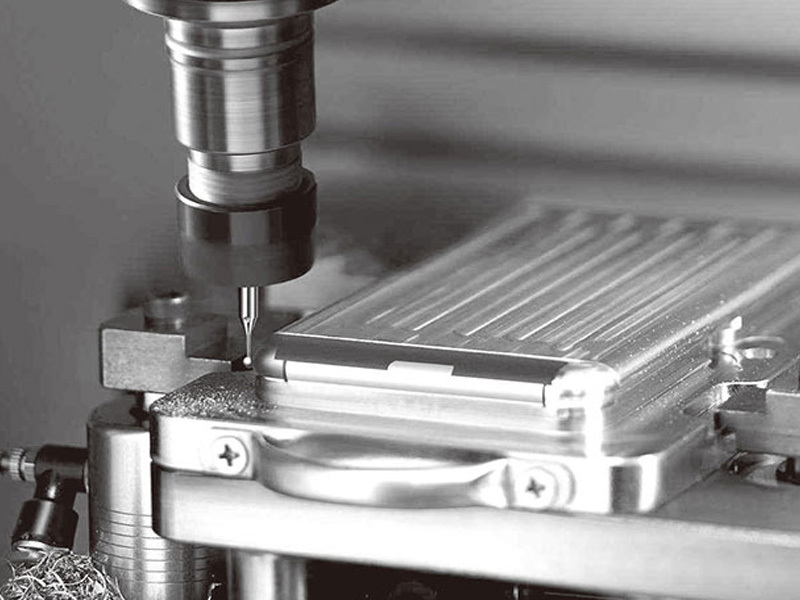

If you want to produce a surface layer that meets the conditions at a certain position in the processing of hardware parts, you must use a hardware processing CNC lathe to occupy a certain proper position compared with special tools before starting mechanical processing. This process is generally called For parts positioning, after the precise positioning of hardware parts, after all, it will be affected by cutting speed and force during precision metal processing.

It is also necessary to use a certain mechanism to clamp the parts to keep them consistent in a clear position. The process of parts from positioning to clamping is called assembly. Below, Yixin Hardware will tell you about the placement of precision metal processing hardware parts , let’s find out together.

Precision metal processing The placement of hardware parts is a very important part of mold manufacturing, which will greatly affect the final processing accuracy, product clamping speed and clamping stability, and it will also affect the overall productivity , in order to ensure the accuracy of the positional relationship between the processed surface and the customized standard, the standard relative equipment of the processed surface should be used to occupy the appropriate position when the hardware parts are placed, and the parts must be in line with the design reference during construction. Overlap with the shaft copper core cable of the spindle bearing of the machine tool;

When processing parts on different high-precision metal processing CNC lathes, there are many different placement methods. The key placement methods can be summarized into three types: alignment method, line alignment method, and tooling and fixture installation:

1. Find the right way directly

When using this method, the metal processing parts occupy a proper position in the equipment, which is obtained through a series of explorations. The specific method is to clamp the hardware parts directly on the CNC lathe, and use the inner diameter dial indicator or dial The stylus on the top is used to calibrate the correct position of the parts by estimation, and verify the levelness at the same time until it meets the requirements;

The positioning accuracy and leveling speed of direct de-rectification both depend on the accuracy of leveling and its leveling method, a method of leveling and the technical level of specific operators. The efficiency is not high, and many of them must be operated with practical experience, and the requirements for operators are relatively high.

Therefore, it is generally used in the production of spare parts, prototypes or small batches, and when there is a relatively high requirement for the precise positioning accuracy of the parts, for example, the deviation accuracy is only allowed to be within 0.01~0.03mm. It is difficult to meet the standard when using fixtures. Therefore, it is necessary to use precise measuring instruments, and operators with relatively high technical levels must use direct positioning to achieve accurate positioning of the product.

2. Find the correct method by drawing a line

This method is to use the scribing needle on the machine equipment to level the hardware according to the line drawn in the blank or semi-finished product processing, so that it can get a proper area. Obviously, this method should have a scribing process. The scribe itself has a certain width, and there will be deviations when scribing, and the deviation needs to be observed when calibrating the parts of the metal processing parts. Therefore, this method is more suitable for small batches and blanks. The accuracy is very low and it is inconvenient to process large hardware parts in the initial processing process of tooling and fixtures.

3. Choose the way of fixture

Tooling fixture is an additional equipment of hardware processing machine. It has adjusted the gold position in advance when the relative CNC blade position in the equipment is not installed in the hardware processing parts, so it is not necessary to adjust the level one by one in the case of producing large quantities of parts. Accurate positioning can ensure the technical requirements of production and processing. It is convenient and convenient, and can effectively improve the efficiency of positioning. It is more suitable for large-volume hardware parts processing.

Latest News