Information Details

What should be paid attention to when grinding metal mold parts after precision metal processing?

Release time:

2023-06-06 16:01

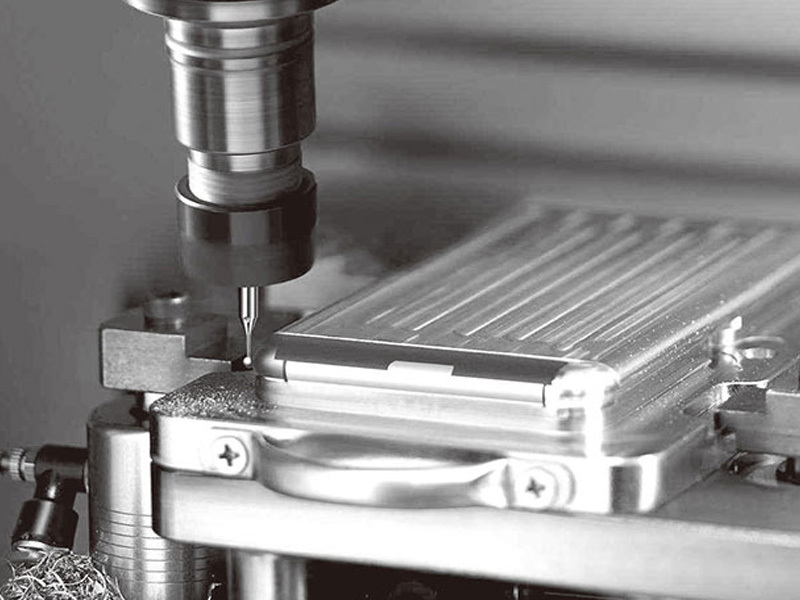

Grinding is a process that metal mold parts often carry out after long-term use. The abrasive particles embedded on the grinding tool will finish the surface of the workpiece during the grinding process. During the relative movement between the grinding tool and the workpiece, the rust and damage on the surface of the metal mold parts after precision metal processing will be It is gradually smoothed and becomes smoother.

The metal mold parts after the grinding process will have a longer service life, and the processing effect will be more significant. So what should be paid attention to when grinding high-quality metal mold parts? The following three points:

1. Pay attention to the order of use of grinding abrasives

Even high-quality metal mold accessories need to use grinding abrasives in a certain order when grinding, which must be from large particles to small particles, from coarse abrasives to fine abrasives. And in order to avoid the phenomenon of "relief".

Second, pay attention to the correct use of abrasives

In order to avoid scratches on the surface of metal mold parts, only abrasives of the same particle size can be used in the same grinding tool, and the surface of metal mold parts must be carefully cleaned before changing the particle size each time, so as to avoid residual large-grained abrasives in the next step. Damage to accessories during the process.

3. Pay attention to the correct operation of grinding with different particle sizes

Efficient and professional metal mold parts grinders grind precision mold parts, and when switching to the next grain size grinding process, the grinding direction will form an angle of about 30 degrees with the previous grinding direction, because it is not easy Scars appear. If scratches appear during the conversion operation, they should be fully trimmed to remove pits.

Latest News