Information Details

4 advantages of 5-axis CNC machining of precision parts

Release time:

2023-04-28 10:42

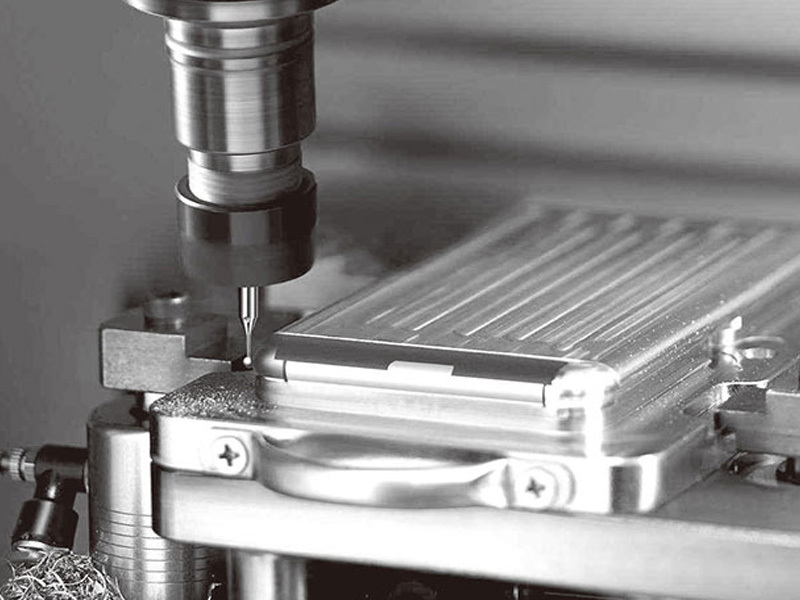

Customized manufacturing of precision molds, especially auto parts molds, medical precision molds, electronic precision molds, etc., plus precision injection molding processing, to provide high-quality injection molding parts for global customers. In the production process of molds, especially complex and precise mold processing, 5-axis CNC machining centers are very much needed. The company has the world's most advanced 5-axis machining centers such as Germany Heimer C22, C42, and C62.

Design engineers looking to produce complex geometries with greater productivity and precision should look for manufacturers with 5-axis CNC machining capabilities. Why? This form of subtractive manufacturing is superior to traditional 3-axis CNC machining in many ways. Let's see how.

5-axis CNC machining vs. 3-axis CNC machining

A standard 3-axis CNC machine can move a part or tool in three axes:

X (side to side)

Y (front and back)

Z (up and down)

5-axis CNC machines add the following approaches to parts:

B (rotate)

C (tilted)

For example, 3-axis machining is like the ability of an aircraft to move forward, laterally, and up and down. You can think of 5-axis machining as the ability of an aircraft to have all of the above plus roll and pitch. the

Ultimately, the ability to access a part from five of its six sides means you can do more machining with fewer setups and with greater precision.

Benefits of 5-axis CNC machining

1. speed

You can often increase cycle times and get jobs done faster with 5-axis CNC machining compared to traditional 3-axis machining because 5-axis technology reduces the number of setups required for each part. With 3-axis machining, every time you need a different side of the part to face the tool, you have to stop the machine, manually loosen the part, manipulate or rotate the part, re-clamp it, and start the machine again. Whereas on a 5-axis machine, you can simply rotate one axis.

5-axis machines also reduce product development time due to reduced setup, allowing you to get first article parts faster and determine the tooling, fixture setup and other details you need before a production run.

2. Accuracy

By eliminating multiple setups, human error is less likely to occur during 5-axis machining than with traditional 3-axis machining. When you can get more work done with fewer operations, you reduce the chances of tolerances accumulating, which reduces problems.

Depending on the complexity of the parts you need to produce and your industry, 5-axis CNC machining may be your only option to achieve the precision and tolerances you need.

3. Return on investment

While 3-axis CNC machining may seem like a lower-cost approach, savvy contract manufacturers will be able to quickly determine whether 5-axis CNC machining has a better return on investment. Based on factors including part complexity, the reduced set-up offered by a 5-axis machine often ends up making it the better choice.

4. Material versatility

All materials are compatible with 5-axis CNC machining processes, including plastics and metals such as aluminium, steel or titanium. Five-axis CNC machining can handle all the same materials as three-axis CNC equipment. the

Industries for 5-axis CNC machining

Many types of parts are amenable to 5-axis CNC machining, but manufacturers in the aerospace and medical fields are particularly well-suited for this approach.

Aerospace parts are well suited for 5-axis CNC machining because many of them have tight tolerances. Additionally, aerospace components are often complex and may have annotations on their part drawings, true position curves, and other requirements that reference surfaces on many sides of the part. The 5-axis approach is better designed to meet all of these specifications simultaneously, improving the chances that the parts will fit as expected and you won't have items that are out of true position or have incorrect contours. Likewise, medical parts often have complex surfaces and require tight tolerances, which also require the precision of 5-axis CNC machining.

Latest News