ABOUT US

Mold manufacturing/metal stamping/professional drawing processing

C.Q.S. Hardware Product is a subsidiary of Taiwan Yaofeng Industrial Co., Ltd. Yaofeng Industrial was established in Taichung, Taiwan Province, China in 1971. When it was first established, it mainly made some small hardware parts. Later, it gradually assisted customers in mold development, design, manufacturing, and some simple finished products for export.As our main customers gradually moved to mainland China, in order to serve customers conveniently, we established Xinyili Industrial Co., Ltd. in Huizhou, Guangdong Province, China in 2001 and C.Q.S. Hardware Productin Jiangmen, Guangdong Province, China in 2005. C.Q.S. Hardware processes hardware, develops and designs molds, manufactures and assembles hardware as the main finished product, and hopes to have the opportunity toserve more customers in the future.We are highly regarded in the industry for our integrity, strength,quality, and adherence to a customer-centric business philosophy of "quality first, service first" (quality and service first). It is our goal to provide our customers with the highest-quality service.

Application

Scroll Through

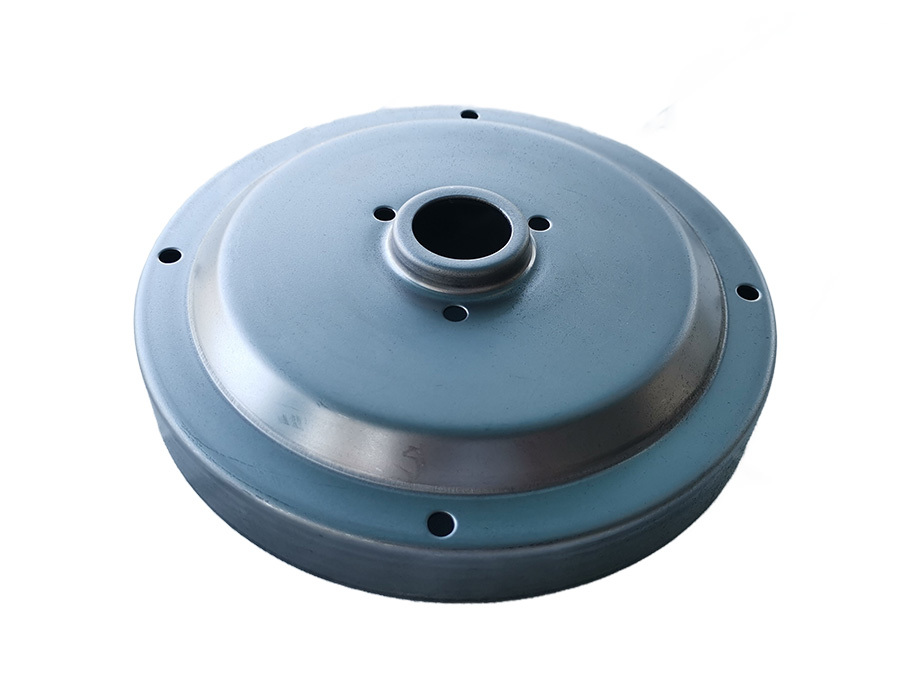

PRODUCT CENTER

OUR ADVANTAGES

Focus on professional

More than 20 years of focus on metal parts stamping and mold manufacturing

Fast delivery

Strict technical supervision, quality and quantity delivery

Quality Assurance

We are highly recognized by the industry for our integrity, strength and quality

Professional team

Mainly process hardware for customers, develop and design molds

Excellent service

Customer interests first, need what customers need, think what customers think

Fully equipped

Welcome friends from all walks of life to visit, guide and negotiate business

EQUIPMENT & TECHNOLOGY

We care. You rest assured😇.

rounding machine

folding machine

250 tons pneumatic punch

250 tons hydraulic press

800 tons hydraulic press

4 advantages of 5-axis CNC machining of precision parts

Customized manufacturing of precision molds, especially auto parts molds, medical precision molds, electronic precision molds, etc., plus precision injection molding processing, to provide high-quality injection molding parts for global customers. In the production process of molds, especially complex and precise mold processing, 5-axis CNC machining centers are very much needed. The company has the world's most advanced 5-axis machining centers such as Germany Heimer C22, C42, and C62.

More04-28

2023

06-06

What is the application range of hardware processing hardware products?

Auxiliary and accessory finished products of hardware used in daily life and industrial manufacturing. Gold, silver, copper, iron, tin and other metal materials were commonly used at first, so it is famous. In addition to various metal materials, non-metallic materials such as plastics and fiberglass are also widely used. The following small hardware processing editor introduces:

06-06

What should be paid attention to when grinding metal mold parts after precision metal processing?

Grinding is a process that metal mold parts often carry out after long-term use. The abrasive particles embedded on the grinding tool will finish the surface of the workpiece during the grinding process. During the relative movement between the grinding tool and the workpiece, the rust and damage on the surface of the metal mold parts after precision metal processing will be It is gradually smoothed and becomes smoother.

06-06

What are the placement methods of hardware parts in precision metal processing?

If you want to produce a surface layer that meets the conditions at a certain position in the processing of hardware parts, you must use a hardware processing CNC lathe to occupy a certain proper position compared with special tools before starting mechanical processing. This process is generally called For parts positioning, after the precise positioning of hardware parts, after all, it will be affected by cutting speed and force during precision metal processing.

06-06

What are the punching and layout forms of different shapes of hardware processing?

Hardware processing usually carries out different steps of processing according to different processing needs of customers, and then arranges processing. The following editor will talk about the processing methods of small hardware processing.